- This topic has 10 replies, 3 voices, and was last updated 4 days, 14 hours ago by doug shank.

-

AuthorPosts

-

July 2, 2024 at 11:43 pm #1229Jim SachetModerator

Rock cutting, polishing, finishing, making cabs, settings, wire wrapping, etc. Post photos of you latest projects.

October 24, 2024 at 1:44 pm #1265doug shankModeratorThe club has acquired some lapidary equipment. This is a Lortone BA-66 cabbing machine.

October 24, 2024 at 1:45 pm #1266doug shankModerator

October 24, 2024 at 1:45 pm #1266doug shankModeratorthis is a Lortone QT-12 Tumbler.

October 24, 2024 at 1:48 pm #1267doug shankModerator

October 24, 2024 at 1:48 pm #1267doug shankModeratorThis is a before photo of the cabbing machine.

October 24, 2024 at 1:50 pm #1268doug shankModerator

October 24, 2024 at 1:50 pm #1268doug shankModeratorthis is a before photo of the tumbler.

March 10, 2025 at 12:13 am #1352doug shankModerator

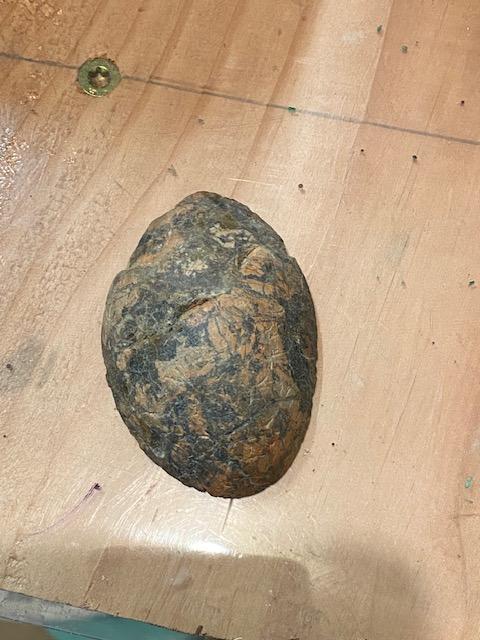

March 10, 2025 at 12:13 am #1352doug shankModeratorHere are three of my latest cabochons (cabs).

This was just a rock in the tumbler until I pulled it out and made a cab out of it. Too bad the chalcedony on the top isn’t clear or it would have been really nice.

This is Biggs jasper with a quartz crystal seam. This was a very mishapen cabochon that I fixed and cleaned up. I think it came out better than expected.

This is called Idaho Seam agate. I bought a small piece of rough at a show for $30 because I have never seen or heard of it before. The bad part was this is the only good piece out of the whole rock. The rest was just cracked to pieces.

- This reply was modified 10 months, 1 week ago by doug shank.

October 18, 2025 at 1:43 am #1411Al WaldParticipantDoug, these cabs are beautiful. You are a master!

I am curious if there are some hints or suggestions you can offer for getting this degree of polish. Were these tumbled to get them started, and then finished on a lap sander?

Al Wald, the curious

October 27, 2025 at 10:45 pm #1412doug shankModeratorSorry for the late reply. I do a lot of cabbing, but I still don’t think I have mastered it yet. There really isn’t a secret to getting a great polish on a cab. Generally you follow a standard of the first grind or shaping on the 80 grit hard wheel followed by further shaping and smoothing and doming on the 220 hard wheel. Then it’s time to move on to the soft resin 280 diamond wheel. Here you will start to remove the scratches left from the steel coarse wheels. It is highly advise not to move from the 280 wheel until you have removed all the deep scratches. Next is the 600 soft diamond wheel where you will remove the scratches form the 280 grit wheel. The 600 is followed by the 1200 grit wheel. By this time most of the scratches should be gone, but if there are some that won’t come out, you will have to go back at least one wheel to remove them or back to the 280. It’s during the 1200 wheel when you will know if you got the scratches out or not. Don’t leave the 1200 until you are sure the scratches are gone. Now you’re ready for the 3000 wheel. Here you should not see any more scratches and you should start seeing a very nice polish. You can continue with polishing on the 6000 grit, 14,000 and 50,000 grit wheels if you have them. This is a usual process, however, it depends on what type of stone you are working with. Some agates can be very tough whereas some really hard jaspers can be a breeze. That is where experience comes in play.

There is a monthly feature article in Rock & Gem magazine called, What To Cut by Russ Kaniuth. He always gives his method for cabbing each stone he cuts.

- This reply was modified 2 months, 2 weeks ago by doug shank.

October 27, 2025 at 10:52 pm #1414doug shankModeratorThanks for the compliments Al. I wish I knew more about the geology of Washington like you do. Here are a few cabs from this week, 10/27/2025

- This reply was modified 2 months, 2 weeks ago by doug shank.

January 8, 2026 at 1:29 pm #1509doug shankModeratorHere are a few before and after photos of some recent cabochons I made:

Willow Creek jasper:

Some type of dendritic jasper:

Jasper/agate:

Montana agate:

Brecciated jasper

-

AuthorPosts

- You must be logged in to reply to this topic.